Overview

LPM (M) explosion-proof plenum pulse bag filter is introduced from Fuller Company of the United States with the advanced level of high efficiency bag dust collector in the 21st century.

It combines the advantages of various bag dust collectors such as chamber back blowing and pulse blowing for dust cleaning, overcoming the insufficient strength of chamber back blowing for dust cleaning and the simultaneous use of pulse blowing for dust cleaning and filtering. Therefore, it expands the application range of bag dust collectors. Due to the unique structure of this type of dust collector, it improves dust collection efficiency and extends the service life of filter bags.

The LPM (M) explosion-proof Plenum pulse bag filter has the characteristics of advanced technology and novel structure. It adopts anti-static needle punched felt filter material, and each room has explosion-proof devices. Various electronic control components also have explosion-proof performance. The dust collector structure also adopts special design. Due to the use of high-voltage offline dust cleaning, the dust collection efficiency is high and can operate efficiently for a long time. Very suitable for coal powder preparation systems and collection of flammable and explosive dust.

Working mechanism

When the dusty gas enters the dust collector from the inlet, it first hits the inclined partition in the middle of the inlet and outlet, and the airflow turns to flow into the hopper, playing a role in pre dust collection. The airflow entering the hopper then turns upward and passes through the filter bag with a metal skeleton inside. The dust is captured on the outer surface of the filter bag, and after purification, the gas enters the clean room at the upper part of the filter bag chamber and is collected and discharged through the outlet duct. The air inlet of the 32 type dust collector is located on the hopper. After the airflow enters the hopper, it first collides with the baffle at the end of the air duct, and its function is the same as the above principle. The case is divided into several independent dust collection chambers by partitions, and each dust collection chamber is cleaned alternately at given time intervals. Each dust collection chamber is equipped with a lift valve. During dust cleaning, the lift valve is closed to cut off the filtered airflow through the chamber. Then, the pulse valve is opened to spray high-pressure air into the filter bag to remove the dust trapped on the outer surface of the filter bag. The pulse blowing width and cleaning cycle of each dust collection chamber are automatically and continuously controlled by a dedicated cleaning program controller .

Main component

This series of dust collector is composed of case , hopper, ash discharge device, explosion-proof door device, support and pulse ash cleaning system.

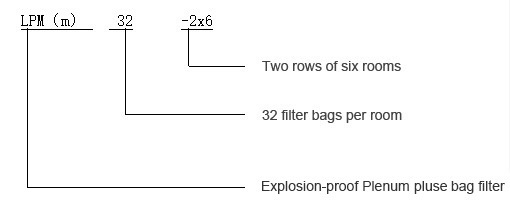

model description

Technical innovation points:

1, This series of dust collectors consists of various specifications with different numbers of chambers and bags per chamber. There are four types of bags in each room: 32, 64, 96, and 128 bags. The whole series has a total of 33 specifications, the diameter of the filter bag is 130mm, and the length of the filter bag is 2450mm and 3060mm.

2, This series of dust collectors can operate under negative or positive pressure without any changes to the body structure. Its dust collection efficiency can reach over 99.9%, and the dust concentration of the purified gas is less than 50mg/m3 (standard). The main technical performance of this series of dust collectors are shown in Tables 1, 2, 3, and 4 .

3. If this series of dust collectors is used in cold regions and the outdoor heating calculation temperature is ≤ -25 ℃, a heating device should be added, and the shell of the dust collector should also be changed accordingly.

4, The characteristic of the explosion-proof Plenum pluse bag filter is the use of separate chambers for alternating dust cleaning, also known as offline dust cleaning. When a certain room is undergoing dust blowing and cleaning, the filtered airflow is cut off, avoiding the secondary flying of dust generated by dust blowing and cleaning. So the explosion-proof Plenum pluse bag filter can capture gases with a dust concentration of up to 1000g/m3(standard).

5, the material of this series of dust collector filter bag is made of anti-static polyester needle felt, allowing continuous use of temperature less than 110℃.

LPM32 (M) explosion-proof Plenum pulse bag filter Technical performance Table 1

| Specification | 32-2(M) | 32-3(M) | 32-4(M) | 32-5(M) | 32-6(M) | ||||

| Technical performance | Reference value for processing gas flow (m3/h) | 1767 | 3534 | 5301 | 7068 | 8838 | |||

| Note: The above reference value is calculated according to the net filtration wind velocity of 0.95m/min. If it changes, the above smoke value will also change accordingly. | |||||||||

| Total filtration area (m2) | 62 | 93 | 124 | 155 | 186 | ||||

| Net filtration area (m2) | 31 | 62 | 93 | 124 | 155 | ||||

| Number of dust collector chambers (units) | 2 | 3 | 4 | 5 | 6 | ||||

| Total filter bags (pcs) | 64 | 96 | 128 | 160 | 192 | ||||

| Dust collector resistance(pa) | 1470~1770 | ||||||||

| Inlet dust concentration g/m3 (standard) | <100 | ||||||||

| Outlet dust concentration mg/m3 (standard) | <50 | ||||||||

| Dust collector under negative pressure(pa) | 5000 | ||||||||

| Filter bag specifications and materials | ¢130×2450 anti-static polyester needle felt operating temperature < 90℃ | ||||||||

| Compressed air pressure for dust cleaning | Pressure (pa) | (5~7)×105 | |||||||

| Air consumption m3/min (standard) | 0.13 | 0.27 | 0.37 | 0.46 | 0.55 | ||||

| Explosion-proof pulse valve (with solenoid valve) | Quantity (pcs) | 2 | 3 | 4 | 5 | 6 | |||

| Size (inches) | 1 1/2 | ||||||||

| Lifting valve (cylinder) | Quantity (pcs) | 2 | 3 | 4 | 5 | 6 | |||

| Size (mm) | Valve plate diameter ¢460 Cylinder diameter ¢63 | ||||||||

| Ash removal device | Spiral conveyor | Specification | |||||||

| Gear motor | |||||||||

| Air transfer chute | |||||||||

| Star shaped unloader | 200×200 | 300×300XWD1.1-3-1/29 | |||||||

| Explosion-proof ash cleaning controller | Input voltage (V) 220 Output voltage (V) 220 | ||||||||

| Insulation layer area(m2) | 20 | 29 | 36 | 43 | 49 | ||||

| Total weight of equipment (excluding insulation) (kg) | 2480 | 3180 | 4480 | 5780 | 7080 | ||||

Technical parameters of LPM64 (M) explosion-proof Plenum pulse bag filter Table 2

| Specification | 64-4(M) | 64-5(M) | 64-6(M) | 64-7(M) | 64-8(M) | ||||

| Technical performance | Reference value for processing gas flow(m3/h) | 10773 | 14364 | 17955 | 21546 | 24137 | |||

| Note: The above reference value is calculated according to the net filtration wind velocity of 0.95m/min. If it changes, the above smoke value will also change accordingly. | |||||||||

| Total filtration area(m2) | 252 | 315 | 373 | 441 | 504 | ||||

| Net filtration area(m2) | 189 | 252 | 315 | 378 | 441 | ||||

| Number of dust collector chambers (units) | 4 | 5 | 6 | 7 | 8 | ||||

| Total filter bags (pcs) | 256 | 320 | 384 | 448 | 512 | ||||

| Dust collector resistance(pa) | 1770 | ||||||||

| Inlet dust concentration g/m3(standard) | <1000 | ||||||||

| Outlet dust concentration mg/m3(standard) | <50 | ||||||||

| Dust collector under negative pressure(pa) | 5000 | ||||||||

| Filter bag specifications and materials | ¢130×2450 anti-static polyester needle felt operating temperature < 90℃ | ||||||||

| Compressed air pressure for dust cleaning | Pressure (pa) | (5~7)×105 | |||||||

| Air consumption m3/min (standard) | 1.2 | 1.49 | 1.8 | 2.1 | 2.4 | ||||

| Explosion-proof pulse valve (with solenoid valve) | Quantity (pcs) | 4 | 5 | 6 | 7 | 8 | |||

| Size (inches) | 2 1/2 | ||||||||

| Lifting valve (cylinder) | Quantity (pcs) | 4 | 5 | 6 | 7 | 8 | |||

| Size (mm) | ¢600 | ||||||||

| Ash removal device | Spiral conveyor | Specification | ¢300 | ||||||

| Gear motor | XWD2.2-5-1/43 | ||||||||

| Air transfer chute | |||||||||

| Star shaped unloader | 300×300 | ||||||||

| Explosion-proof ash cleaning controller | Input voltage (V) 220 Output voltage (V) 220 | ||||||||

| Insulation layer area(m2) | 70 | 94 | 118 | 142 | 166 | ||||

| Total weight of equipment (excluding insulation)(kg) | 8680 | 10460 | 12140 | 13920 | 15750 | ||||

Technical parameters of LPM96 (M) explosion-proof Plenum pulse bag filter Table 3

| Specification | 96-4(M) | 96-5(M) | 96-6(M) | 96-7(M) | 96-8(M) | 96-9(M) | ||||

| Technical performance | Reference value for processing gas flow (m3/h) | 16074 | 21432 | 26790 | 32148 | 37506 | 42864 | |||

| Note: The above reference value is calculated according to the net filtration wind velocity of 0.95m/min. If it changes, the above smoke value will also change accordingly. | ||||||||||

| Total filtration area (m2) | 376 | 470 | 564 | 658 | 752 | 846 | ||||

| Net filtration area (m2) | 282 | 376 | 470 | 564 | 658 | 752 | ||||

| Number of dust collector chambers (units) | 4 | 5 | 6 | 7 | 8 | 9 | ||||

| Total filter bags (pcs) | 384 | 480 | 576 | 672 | 762 | 864 | ||||

| Dust collector resistance(pa) | 1450~1770 | |||||||||

| Inlet dust concentration g/m3(standard) | <1000 | |||||||||

| Outlet dust concentration mg/m3(standard) | ≤50 | |||||||||

| Dust collector under negative pressure(pa) | 5000 | |||||||||

| Filter bag specifications and materials | ¢130×2450 anti-static polyester needle felt operating temperature < 100℃ | |||||||||

| Compressed air pressure for dust cleaning | Pressure (pa) | (5~7)×105 | ||||||||

| Air consumption m3/min (standard) | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | ||||

| Explosion-proof pulse valve (with solenoid valve) | Quantity (pcs) | 4 | 5 | 6 | 7 | 8 | 9 | |||

| Size (inches) | 2 1/2 | |||||||||

| Lifting valve (cylinder) | Quantity (pcs) | 4 | 5 | 6 | 7 | 8 | 9 | |||

| Size (mm) | ¢726 | |||||||||

| Ash removal device | Spiral conveyor | Specification | ¢400 | |||||||

| Gear motor | XWD5.5-7-1/59 | |||||||||

| Air transfer chute | ||||||||||

| Star shaped unloader | 300×300 | |||||||||

| Explosion-proof ash cleaning controller | Input voltage (V) 220 Output voltage (V) 220 | |||||||||

| Insulation layer area(m2) | 115 | 130 | 145 | 160 | 175 | 190 | ||||

| Total weight of equipment (excluding insulation)(kg) | 10950 | 12720 | 15780 | 17720 | 19740 | 22240 | ||||

Technical parameters of LPM96 (M) explosion-proof Plenum pulse bag filter Table 4

| Specification | 96-2x5(M) | 96-2x6(M) | 96-2x7(M) | 96-2x8(M) | 96-2x9(M) | 96-2x10(M) | ||||

| Technical performance | Reference value for processing gas flow (m3/h) | 48222 | 53580 | 64296 | 75012 | 85728 | 96444 | |||

| Note: The above reference value is calculated according to the net filtration wind velocity of 0.95m/min. If it changes, the above smoke value will also change accordingly. | ||||||||||

| Total filtration area (m2) | 940 | 1128 | 1316 | 1504 | 1692 | 1880 | ||||

| Net filtration area (m2) | 846 | 940 | 1128 | 1316 | 1504 | 1392 | ||||

| Number of dust collector chambers (units) | 10 | 12 | 14 | 16 | 18 | 20 | ||||

| Total filter bags (pcs) | 960 | 1152 | 1344 | 1536 | 1728 | 1920 | ||||

| Dust collector resistance(pa) | 1450~1770 | |||||||||

| Inlet dust concentration g/m3(standard) | <1000 | |||||||||

| Outlet dust concentration mg/m3(standard) | ≤50 | |||||||||

| Dust collector under negative pressure(pa) | 5000 | |||||||||

| Filter bag specifications and materials | ¢130×2450 anti-static polyester needle felt operating temperature < 100℃ | |||||||||

| Compressed air pressure for dust cleaning | Pressure (pa) | (5~7)×105 | ||||||||

| Air consumption m3/min (standard) | 3 | 3.4 | 4.2 | 4.8 | 5.4 | 6 | ||||

| Explosion-proof pulse valve (with solenoid valve) | Quantity (pcs) | 10 | 12 | 14 | 16 | 18 | 20 | |||

| Size (inches) | 2 1/2 | |||||||||

| Lifting valve (cylinder) | Quantity (pcs) | 10 | 12 | 14 | 16 | 18 | 20 | |||

| Size (mm) | ¢726 | |||||||||

| Ash removal device | Spiral conveyor | Specification | ¢400 | |||||||

| Gear motor | XWD5.5-7-1/59 | |||||||||

| Air transfer chute | ||||||||||

| Star shaped unloader | 300×300 | |||||||||

| Explosion-proof ash cleaning controller | Input voltage (V) 220 Output voltage (V) 220 | |||||||||

| Insulation layer area(m2) | 190 | 225 | 260 | 295 | 330 | 365 | ||||

| Total weight of equipment (excluding insulation) (kg) | 25950 | 31740 | 36880 | 41320 | 46360 | 52450 | ||||

Technical parameters of LPM128 (M) explosion-proof Plenum pulse bag filter Table 5

| Specification | 128-6(M) | 128-9(M) | 128-10(M) | 128-2x6(M) | 128-2x7(M) | 128-2x8(M) | ||||

| Technical performance | Reference value for processing gas flow(m3/h) | 44754 | 71592 | 80541 | 98436 | 116337 | 134235 | |||

| Note: The above reference value is calculated according to the net filtration wind velocity of 0.95m/min. If it changes, the above smoke value will also change accordingly. | ||||||||||

| Total filtration area (m2) | 942 | 1413 | 1570 | 1884 | 2198 | 2512 | ||||

| Net filtration area (m2) | 785 | 1256 | 1413 | 1727 | 2041 | 2355 | ||||

| Number of dust collector chambers (units) | 6 | 9 | 10 | 12 | 14 | 16 | ||||

| Total filter bags (pcs) | 768 | 1152 | 1280 | 1536 | 1792 | 2084 | ||||

| Dust collector resistance(pa) | 1450~1770 | |||||||||

| Inlet dust concentration g/m3(standard) | <1000 | |||||||||

| Outlet dust concentration mg/m3(standard) | <50 | |||||||||

| Dust collector under negative pressure(pa) | 5880 | 6860 | 7468 | 7500 | ||||||

| Filter bag specifications and materials | ¢130×3058 anti-static polyester needle felt operating temperature < 100℃ | |||||||||

| Compressed air pressure for dust cleaning | Pressure (pa) | (5~7)×105 | ||||||||

| Air consumption m3/min (standard) | 2.4 | 5.4 | 6 | 7 | 8.3 | 9.5 | ||||

| Explosion-proof pulse valve (with solenoid valve) | Quantity (pcs) | 12 | 18 | 20 | 24 | 28 | 32 | |||

| Size (inches) | 2 1/2 | |||||||||

| Lifting valve (cylinder) | Quantity (pcs) | 6 | 9 | 10 | 12 | 14 | 16 | |||

| Size (mm) | ¢226 | |||||||||

| Ash removal device | Spiral conveyor | Specification | ¢400 | |||||||

| Gear motor | XWD5.5-7-1/59 | |||||||||

| Air transfer chute | ||||||||||

| Air locking device | Rigid impeller feeder | 300×300 | ||||||||

| Explosion-proof ash cleaning controller | Input voltage (V) 220 Output voltage (V) 220 | |||||||||

| Insulation layer area(m2) | 140 | 210 | 220 | 240 | 260 | 275 | ||||

| Total weight of equipment (excluding insulation)(kg) | 26120 | 32680 | 36680 | 45920 | 54680 | 62000 | ||||

Technical parameters of LPM128 (M) explosion-proof Plenum pulse bag filter Table 6

| Specification | 128-2x9(M) | 128-2x10(M) | 128-2x11(M) | 128-2x12(M) | 128-2x13(M) | 128-2x14(M) | ||||

| Technical performance | Reference value for processing gas flow (m3/h) | 152133 | 170031 | 187929 | 205827 | 223725 | 241623 | |||

| Note: The above reference value is calculated according to the net filtration wind velocity of 0.95m/min. If it changes, the above smoke value will also change accordingly. | ||||||||||

| Total filtration area (m2) | 2826 | 3140 | 3454 | 3768 | 4082 | 4396 | ||||

| Net filtration area (m2) | 2669 | 2983 | 3297 | 3611 | 3925 | 4239 | ||||

| Number of dust collector chambers (units) | 18 | 20 | 22 | 24 | 26 | 28 | ||||

| Total filter bags (pcs) | 2304 | 2560 | 2816 | 3072 | 3328 | 2584 | ||||

| Dust collector resistance(pa) | 1450~1770 | |||||||||

| Inlet dust concentration g/m3(standard) | <1300 | |||||||||

| Outlet dust concentration mg/m3(standard) | <50 | |||||||||

| Dust collector under negative pressure(pa) | 7000 | |||||||||

| Filter bag specifications and materials | ¢130×3058 anti-static polyester needle felt operating temperature < 110℃ | |||||||||

| Compressed air pressure for dust cleaning | Pressure (pa) | (5~7)×105 | ||||||||

| Air consumption m3/min (standard) | 10.7 | 12 | 13.1 | 14.3 | 15.6 | 16.7 | ||||

| Explosion-proof pulse valve (with solenoid valve) | Quantity (pcs) | 36 | 40 | 44 | 48 | 52 | 56 | |||

| Size (inches) | 2 1/2 | |||||||||

| Lifting valve (cylinder) | Quantity (pcs) | 18 | 20 | 22 | 24 | 26 | 28 | |||

| Size (mm) | ¢726 | |||||||||

| Ash removal device | Spiral conveyor | Specification | ¢400 | |||||||

| Gear motor | XWD5.5-7-1/59 | |||||||||

| Air transfer chute | ||||||||||

| Air locking device | Rigid impeller feeder | ¢300 | ||||||||

| Explosion-proof ash cleaning controller | Input voltage (V) 220 Output voltage (V) 220 | |||||||||

| Insulation layer area(m2) | 290 | 315 | 320 | 335 | 350 | 365 | ||||

| Total weight of equipment (excluding insulation)(kg) | 68480 | 74000 | 80480 | 88400 | 96600 | 105800 | ||||