Rotating low-pressure jet pulse dust collector technology

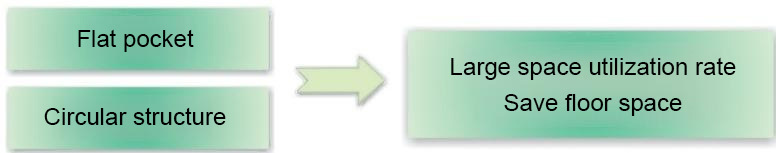

The rotary low-pressure jet pulse dust collector is an efficient bag dust collector independently developed by our company based on advanced technology of rotary jet bag dust collectors at home and abroad, summarizing the advantages and disadvantages of various flat bag dust collectors in China. This dust collector adopts a circular structure, with uniform force distribution and good anti explosion performance, and is installed outdoors. This type of machine has a compact structure, high dust removal efficiency, low resistance, easy operation, convenient maintenance and reliable operation.

The filtered air is input into the air storage tank using a Roots blower, and then compressed air is instantly sprayed into the filter bag through the nozzle at the lower part of the rotating arm to achieve the purpose of dust cleaning. This low-pressure atmospheric pulse jet cleaning system is not limited by gas source conditions and uses resistance to automatically control the jet cleaning, saving energy and extending the service life of the bag. It can be widely used in many departments such as metallurgy, chemical industry, cement, building materials, grain chemical industry, etc. It is a dust removal equipment with high purification efficiency, energy saving, and superior performance. Since its launch on the market, this product has been well received by users.

ROTATING INJECTION PULSE DUST COLLECTOR STRUCTURE CHART

main parts

Inlet smoke cases ,filter bag, tube nest,diaphragm valve ,drive motor, ash bucket, door,vent pipe,filter cage, Pipe cleaning,frame,platform stair

Technological Innovation

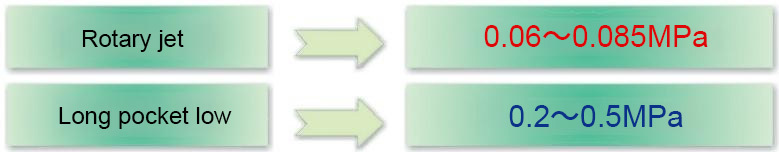

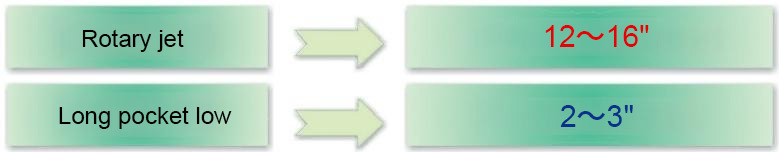

Using Low-pressure pulse cleaning dust,extend the life of the bag to 20%-40%

large diameter pulse valve-- a small number and less control points ,easy to determine the fault location pulse valve,easy to replace the filter bag

the flat bag , circular structure, saving footprint

Related Tech